APPLICATIONS OF INTERNAL COMBUSTION

ENGINES

1.

Automotive: (i)

Car

(ii) Truck/Bus

(iii) Off-highway

2. Locomotive

3. Light Aircraft

4. Marine:

(i) Outboard

(ii)

Inboard

(iii)

Ship

5. Power Generation: (i)

Portable (Domestic)

(ii) Fixed (Peak Power)

6. Agricultural: (i)

Tractors

(ii)

Pump sets

7. Earthmoving: (i)

Dumpers

(ii)

Tippers

(iii)

Mining Equipment

8. Home Use: (i) Lawnmowers

(ii) Snow blowers

(iii) Tools

9. Others

BASIC TERMS

REGARDING ENGINES

01)Bore

The inside Diameter of

the Cylinder is known as the Bore and it is measured in millimeter (mm).

02) Stroke

It is the distance travelled

by the Piston from one of its dead centre position to the other dead centre

position.

03) Dead Centre

They corresponds to the

positions occupied by the piston at the end of its Stroke,where the centre line

of the Connecting Rod and Crank are in the same straight line.For Vertical

Engines these are known as Top Dead Centre (T.D.C) and Bottom Dead Centre

(B.D.C) position.In Horizontal Engines,these are known as Inner Dead Centre

(I.D.C) and Outer Dead Centre (O.D.C) position.

04) Top Dead Centre

In Vertical Engines,the

top most position of the Piston towards the cover end side of the cylinder is

known as Top Dead Centre.

05) Bottom Dead Centre

In Vertical Engines,the

lower position of the Piston towards the Crank end side of the cylinder is known

as Bottom Dead Centre.

06) Piston Displacement

It is also known as

"Swept Volume".It is the volume through which the Piston sweeps for

its one Stroke.It is equal to the Area of cross section of the Piston

multiplied by its Stroke Length.

07) Clearance Volume

It is the Volume included

between the Piston and the Cylinder Head when the Piston is at its Top Dead

Centre in Vertical Engines and inner Dead Centre in Horizontal Engines.The

Clearance Volume is generally expressed as percentages of Swept Volume.

08) Compression Ratio

It is the ratio of the

total Cylinder Volume to the Clearance Volume.For Petrol Engines the value of

Compression Ratio is varies from 5:1 To 9:1 and for Diesel Engines varies from

14:1 To 22:1

09) Piston Speed

It is the distance

travelled by the Piston in one minute.The piston Speed=2LN meter/min.If the

R.P.M. of Engine Shaft=N and length of Stroke=L meter.

10) Crank Throw

This is the distance

between the Centre of Crankshaft and Centre of Crank Pin.The distance will be equal

to half the Stroke Length

11) Carburetion

The process of breaking

up the fuel into minute particles and mixing it with air is called

"Carburetion". This process is mostly used in the internal combustion

engine, which have low compression ratio and which use highly volatile liquid

fuels such as petrol. The process of breaking up fuel in minute particles is

known as "Atomization". Carburettor is the device where all the

carburetion takes place.

12) Scavenging

The process of removing

burnt exhaust gases from the combustion chamber of the engine cylinder is known

as "Scavenging". In four-stroke cycle engine, the piston pushes the

burnt gases to exhaust manifold during its exhaust stroke. In the two-stroke

cycle engine a blast of fresh charge is made to enter at higher velocity into a

combustion chamber at the end of working stroke and thus drives out burnt

exhaust gases.

13) Compensation

The process of providing

additional fuel or reducing the fuel by certain means to correct the mixture

strength to meet the varying nature of speeds and load on the engines is known

as "Compensation". This process is mostly used in simple carburettor

specially used for automotive purposes.

14) Firing Order

The sequences in which

firing or power impulses occur in an internal combustion engine are called

"Firing Order". The firing order should be such that there is always

a proper balance and it does not cause vibrations.

15) Detonation

Some sudden and violent

knocks are experienced in internal combustion engine at sometimes. This knocks

are known by "Detonation". This knock is set up by a high pressure

wave giving a loud pulsating noise as it strikes against the cylinder walls,

cylinder head and piston. It should be noted that detonation is not pre-ignition

but something, which occur after the spark, has started the ignition.

16) Doping

The process of adding

small quantity of Tetraethyl lead to suppressed the detonation in petrol engine

is called "Doping". If the tetraethyl lead used in large proportion,

there are chances of engine damage due to deposition of lead oxide in the

combustion chamber.

17) Diesel Knock

A high pressure wave set

up in compression ignition engine (Diesel Engine), which causes knocks. This

knock is called as "Diesel knock". It badly affects the engine

efficiency and power drop; also engine runs very rough due to diesel knock.

18) Dissociation

If a gas or mixture of

gases is heated to very high temperature, the vibrating molecules of different

gases make violent encounters resulting in splitting up of the compound

molecules into smaller molecules which recombine to form their compound

molecules as the temperature lowered. The phenomenon is called

"Dissociation". The dissociation is mainly due to breaking up of

carbon dioxide into carbon monoxide and oxygen.

19) Supercharging

The process of increasing

the weight or density of air-fuel mixture or compressed air, induced into the

cylinder during the induction stroke is known as "Supercharging".

This is achieved by a separate compressor and known as supercharger or blower.

20) Turbulence

When the atomised fuel

injected into the combustion chamber of compression ignition engine may be

burnt efficiently there should be a high relative velocity between the air and

fuel so that a thorough mixing takes place. This is achieved by

"Turbulence".

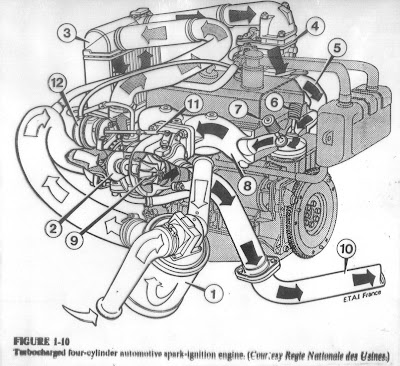

GENERAL

VIEW OF AN ENGINE

CLASSIFICATION

OF INTERNAL COMBUSTION ENGINES

-Based on motion, no. of cylinders &

arrangement

1. Reciprocating: (a)

Single Cylinder

(b) Multi-cylinder (I) In-line

(ii) V

(iii) Radial

(iv) Opposed Cylinder

(v) Opposed Piston

2. Rotary: (a) Single Rotor

(b)

Multi-rotor

- Based on no. Of strokes per cycle

1.Four

Stroke Cycle: (a)

Naturally Aspirated

(b)Supercharged/Turbocharged

2.Two

Stroke Cycle:

(a) Crankcase Scavenged

(b) Uniflow Scavenged

(i)

Inlet valve/Exhaust Port

(ii)

Inlet Port/Exhaust Valve

(iii) Inlet and Exhaust Valve

- Based on Operating Cycle

1) Otto (For the Conventional SI Engine)

2) Diesel (For the Ideal Diesel Engine)

3)

Dual (For

the Actual Diesel Engine)

- Based on cooling

1) Water cooled engines

2) Air cooled engines

- Based on type of ignition

1) Spark ignition engine

2) Compression ignition engine

-Based on fuel used

1)

Petrol

engines

2)

Diesel

engines

3)

Gas

engines

CLASSIFICATION IN DETAIL

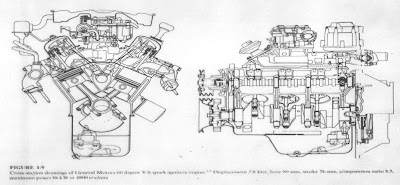

-Based on motion, no. of cylinders & arrangement

1. Reciprocating: (a)

Single Cylinder

(b) Multi-cylinder (I) In-line

(ii) V

(iii) Radial

(iv) Opposed Cylinder

(v) Opposed Piston

2. Rotary: (a) Single Rotor

(b)

Multi-rotor

- Reciprocating Engines

A

reciprocating engine, also often

known as a piston engine, is a heat engine that uses one or more reciprocating pistons to convert pressure into a rotating motion. There may be one or more pistons. Each piston is

inside a cylinder, into which a gas is

introduced, either already hot and under pressure (steam engine), or heated inside the cylinder either by ignition of a fuel air mixture (internal combustion

engine)

or by contact with a hot heat exchanger in the cylinder .The hot gases expand,

pushing the piston to the bottom of the cylinder. The piston is returned to the

cylinder top (Top Dead Centre) either by a flywheel or the power from other pistons connected to the

same shaft. In most types the expanded or "exhausted" gases are removed from the cylinder by

this stroke. The exception is the Stirling engine, which repeatedly heats and cools the same

sealed quantity of gas.

In all types, the linear movement of the

piston is converted to a rotating movement via a connecting rod and a crankshaft or by a swash plate. A flywheel is often used to

ensure smooth rotation. The more cylinders a reciprocating engine has,

generally, the more vibration-free (smoothly) it can operate. The power of a

reciprocating engine is proportional to the volume of the combined pistons'

displacement.

A seal needs to be made between the sliding piston and the walls of the cylinder so that the high

pressure gas above the piston does not leak past it and reduce the efficiency

of the engine. This seal is provided by one or more piston rings. These are rings

made of a hard metal which are sprung into a circular groove in the piston

head. The rings fit tightly in the groove and press against the cylinder wall

to form a seal.

The bore/stroke ratio is the ratio of the

diameter of the piston, or "bore", to the length of travel within the

cylinder, or "stroke". If this is around 1 the engine is said to be

"square", if it is greater than 1, i.e. the bore is larger than the stroke;

it is "over square". If it is less than 1, i.e. the stroke is larger

than the bore; it is "under square".

- ROTARY

ENGINES

(a) Single Rotor

(b) Multi-rotor

Wankel

Engine Parts

In the basic single-rotor Wankel engine, the

oval-like epitrochoid-shaped housing surrounds a rotor which is triangular with

bow-shaped flanks (often confused with a Reuleaux

triangle, a three-pointed

curve of constant width, but with the bulge in the middle of each

side a bit more flattened). The theoretical shape of the rotor between the

fixed corners is the result of a minimization of the volume of the geometric combustion chamber and a maximization of the compression

ratio, respectively. The symmetric curve connecting two arbitrary apexes of the rotor is maximized in the

direction of the inner housing shape with the constraint not to touch the

housing at any angle of rotation (an arc is not a solution of this optimization problem).

The central drive shaft, called

the eccentric shaft or E-shaft, passes through the center of the rotor and is

supported by fixed bearings. The rotors ride on eccentrics (analogous to cranks) integral with the

eccentric shaft (analogous to a crankshaft). The rotors both rotate around the eccentrics and make orbital revolutions around the eccentric shaft. Seals at the

corners of the rotor seal against the periphery of the housing, dividing it

into three moving combustion chambers. The rotation of each rotor on its own

axis is caused and controlled by a pair of synchronizing gears. A

fixed gear mounted on one side of the rotor housing engages a ring gear

attached to the rotor and ensures the rotor moves exactly 1/3 turn for each

turn of the eccentric shaft. The power output of the engine is not transmitted

through the synchronizing gears. The force of gas pressure on the rotor (to a

first approximation) goes directly to the center of the eccentric, part of the

output shaft.

-Based on no. Of strokes per cycle

1.Four

Stroke Cycle: (a)

Naturally Aspirated

(b)Supercharged/Turbocharged

2.Two

Stroke Cycle:

(a) Crankcase Scavenged

(b) Uniflow Scavenged

(i)

Inlet valve/Exhaust Port

(ii)

Inlet Port/Exhaust Valve

(iii) Inlet and Exhaust Valve

-Four

Stroke & Two stroke

The cycle begins at Top Dead Center (TDC), when

the piston is farthest away from the axis of the crankshaft. A stroke refers to the full travel of the piston from Top Dead

Center (TDC) to Bottom Dead Center (BDC). (See Dead centre.)

1. INTAKE stroke: On the intake or induction stroke of the piston, the

piston descends from the top of the cylinder to the bottom of the cylinder,

reducing the pressure inside the cylinder. A mixture of fuel and air is forced by atmospheric (or greater) pressure into the cylinder

through the intake port. The intake valve(s) then close.

2. COMPRESSION stroke: With both intake and exhaust valves closed, the piston returns to the

top of the cylinder compressing the fuel-air mixture. This is known as the compression stroke.

3. POWER stroke.: While the piston is close to Top Dead Center, the compressed air–fuel

mixture is ignited, usually by a spark plug (for a gasoline or Otto cycle engine) or by the heat and

pressure of compression (for a diesel cycle or compression ignition engine). The resulting massive pressure from the combustion of the compressed fuel-air mixture drives the piston back down toward

bottom dead center with tremendous force. This is known as the power stroke, which is the main

source of the engine's torque and power.

4. EXHAUST stroke.: During the exhaust

stroke, the piston once again returns to top dead center while the exhaust

valve is open. This action evacuates the products of combustion from the

cylinder by pushing the spent fuel-air mixture through the exhaust valve(s).

Two-stroke

Engine

A

two-stroke engine is an internal combustion engine that completes the process cycle in one

revolution of the crank shaft (an up stroke and a down stroke of the piston, compared to twice that number for a four-stroke engine). This is accomplished by using the beginning of

the compression stroke and the end of the combustion stroke to perform

simultaneously the intake and exhaust (or scavenging) functions. In this way two-stroke engines often provide

strikingly high specific power, at least in a narrow range of rotations speeds. The

functions of some or all of the valves of a four stroke engine are usually

served by ports that are opened and closed by the motion of the pistons,

greatly reducing the number of moving parts. Gasoline (spark ignition) versions are

particularly useful in lightweight (portable) applications such as chainsaws

and the concept is also used in diesel compression ignition engines in large and non-weight sensitive

applications such as ships and locomotives.

- Based on

Operating Cycle

1) Otto (For the Conventional SI Engine)

2) Diesel (For the Ideal Diesel Engine)

3) Dual (For the Actual Diesel Engine)

OTTO (FOR THE CONVENTIONAL S.I. ENGINE)

The

idealized four-stroke Otto cycle p-V diagram: the intake

(A) stroke is performed by an isobaric expansion, followed by an adiabatic compression (B)

stroke. Through the combustion of fuel, heat is added in an isochoric process, followed by an adiabatic expansion process, characterizing the

power (C) stroke. The cycle is closed

by the exhaust (D) stroke,

characterized by isochoric cooling and isobaric compression processes.

An Otto

cycle is an idealized thermodynamic cycle which describes the functioning of a typical

reciprocating piston engine. The Otto cycle is constructed out of:

The adiabatic processes are impermeable to

heat: heat flows into the loop through the left pressurizing process and some

of it flows back out through the right depressurizing process, and the heat

which remains does the work.

The Otto cycle consists of adiabatic compression, heat

addition at constant volume, adiabatic expansion, and rejection of heat at

constant volume. In the case of a four-stroke Otto cycle, technically there are

two additional processes: one for the exhaust of waste heat and combustion

products (by isobaric compression), and one for the intake of cool oxygen-rich

air (by isobaric expansion); however, these are often omitted in a simplified

analysis. Even though these two processes are critical to the functioning of a

real engine, wherein the details of heat transfer and combustion chemistry are

relevant, for the simplified analysis of the thermodynamic cycle, it is simpler

and more convenient to assume that all of the waste-heat is removed during a

single volume change.

DIESEL (FOR

THE IDEAL DIESEL ENGINE)

- Process 1 to 2 is isentropic

compression (blue)

- Process 2 to 3 is reversible constant pressure heating (red)

- Process 3 to 4 is isentropic expansion (yellow)

- Process 4 to 1 is reversible constant volume

cooling (green)

The Diesel is a heat engine: it converts heat into work. The isentropic processes are impermeable to heat:

heat flows into the loop through the left expanding isobaric process and some

of it flows back out through the right depressurizing process, and the heat

that remains does the work.

- Work in (Win) is done by the piston compressing the working

fluid

- Heat in (Qin) is done by the combustion

of the fuel

- Work out (Wout) is done by the working fluid expanding on to

the piston (this produces usable torque)

- Heat out (Qout) is done by venting the air

- Based on cooling

-Water cooled engines

-Air cooled engines

-WATER COOLED

ENGINES

Liquid cooling is also employed in maritime vehicles. For

vessels, the seawater itself is mostly used for cooling. In some cases,

chemical coolants are also employed (in closed systems) or they are mixed with

seawater cooling. Water cooling is used in those engines where more cooling

effect is required. Most modern internal combustion engines are cooled by a closed circuit carrying liquid coolant through channels in the engine

block, where the coolant absorbs heat, to a heat exchanger or radiator where the coolant releases heat into

the air. Thus, while they are ultimately

cooled by air, because of the liquid-coolant circuit they are known as water-cooled

-AIR COOLED ENGINES

Heat generated by an air-cooled engine is released directly into the

air. Typically this is facilitated with metal fins covering the outside of the cylinders which increase the surface area that air can act on.

In all combustion

engines, a great percentage of the heat generated (around 44%) escapes through

the exhaust, not through either a liquid cooling system nor through the metal

fins of an air-cooled engine (12%). About 8% of the heat energy finds its way

into the oil, which although

primarily meant for lubrication, also plays a role

in heat dissipation via a cooler

-

Based on

type of ignition

1) Spark ignition engine

2) Compression ignition engine

-SPARK IGNITION ENGINE

-COMPRESSION

IGNITION ENGINE

The diesel engine has the highest thermal

efficiency of any

regular internal or external

combustion engine

due to its very high compression ratio. Low-speed diesel engines (as used in

ships and other applications where overall engine weight is relatively

unimportant) often have a thermal efficiency which exceeds 50 percent.

-Based on fuel used

1) Petrol engines

2) Diesel engines

3) Gas engines

PETROL ENGINES

A petrol engine (known

as a gasoline engine in North

America) is an internal combustion engine with spark-ignition, designed to run on petrol (gasoline) and similar volatile fuels.

It differs from a diesel

engine in the method of mixing the fuel and air, and in

the fact that it uses spark plugs to initiate the combustion process. In a diesel

engine, only air is compressed (and therefore heated), and the fuel is injected

into the now very hot air at the end of the compression stroke, and

self-ignites. In a petrol engine, the fuel and air are usually pre-mixed before

compression (although some modern petrol engines now use cylinder-direct petrol

injection).

The pre-mixing was formerly done in a carburetor, but now (except in the smallest engines) it is done by

electronically controlled fuel

injection. Petrol engines run at higher speeds than

Diesels partially due to their lighter pistons, conrods & crankshaft (as a

result of lower compression ratios) & due to petrol burning faster than

diesel. However the lower compression ratios of a petrol engine gives a lower

efficiency than a diesel engine.

DIESEL

ENGINES

A diesel engine (also known as a compression-ignition engine and

sometimes capitalized as Diesel engine)

is an internal combustion engine that uses the heat

of compression to

initiate ignition to burn the fuel, which is injected into the combustion

chamber during the

final stage of compression. This is in contrast to spark-ignition engines such

as a petrol

engine (gasoline

engine) or gas engine (using a gaseous fuel as opposed to

gasoline), which uses a spark plug to ignite an air-fuel mixture.

The fuel

injector ensures that the fuel is broken down into small droplets, and that the

fuel is distributed evenly. The heat of the compressed air vaporizes fuel from

the surface of the droplets. The vapour is then ignited by the heat from the

compressed air in the combustion chamber, the droplets continue to vaporize

from their surfaces and burn, getting smaller, until all the fuel in the droplets

has been burnt. The start of vaporization causes a delay period during

ignition, and the characteristic diesel knocking sound as the vapor reaches

ignition temperature and causes an abrupt increase in pressure above the

piston. The rapid expansion of combustion gases then drives the piston

downward, supplying power to the crankshaft. Engines for scale-model aero

planes use a variant of the Diesel principle but premix fuel and air via a carburetion

system external to the combustion chambers.

GAS

ENGINES

A gas engine means an engine running on

a gas, such as coal gas, producer gas biogas, landfill

gas, or natural gas. Generally the term gas engine

refers to a heavy duty, slow revving industrial engine capable of running

continuously at full output for periods approaching a high fraction of 8,760

hours per year, for many years, with indefinite lifetime, unlike say a gasoline

automobile engine which is lightweight, high revving and typically runs for no

more than 4,000 hours in its entire life. Typical power ranges from 10 kW

to 4,000 kW.